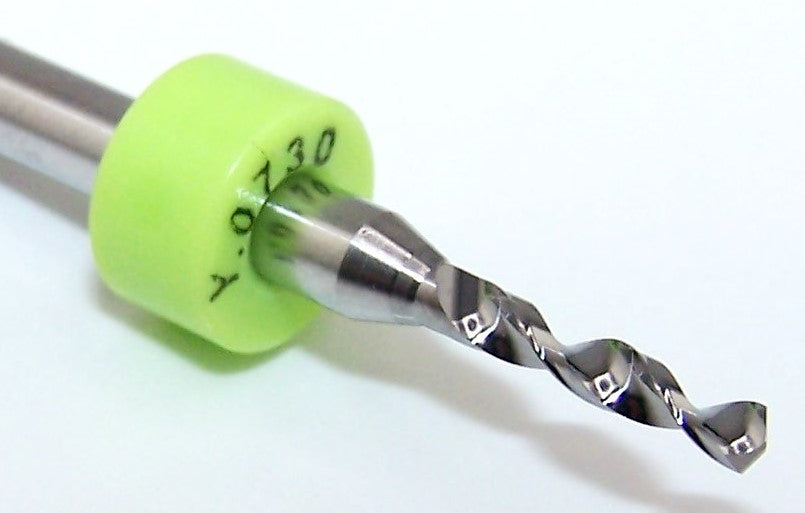

100.0730.400 Kyocera #49 Carbide 2 Flute Drill .0730" Diameter .400" Flute 1.50" Length .125" Shank

100.0730.400 Kyocera #49 Carbide 2 Flute Drill .0730" Diameter .400" Flute 1.50" Length .125" Shank

Part Number: 100.0730.400

SKU: 387519756417

Manufacturer: Kyocera PCB

144 in stock

Couldn't load pickup availability

PRODUCT STATS

| DIAMETER | 0.0730" |

| FLUTE NUMBER | 2 |

| LENGTH OF CUT | 0.4000" |

| OVERALL LENGTH | 1.5" |

| SHANK SIZE | 0.125" |

| SIZE | #49 |

| BRAND | Kyocera PCB |

| CUT DIRECTION | Up Cut |

| ENDS | Single |

| END STYLE | Drill Point |

| FINISH TYPE | Bright |

| FLUTE DIRECTION | Right Hand |

| FLUTE STYLE | Spiral |

| INCLUDED POINT ANGLE | 130.0° |

| MATERIAL | Carbide Tip |

| MATERIALS CUT | Fiberglass, Plastic, Aluminum, Composite Materials, Wood |

| MPN | 100.0730.400 |

Material:

Carbide PCB drills are made from tungsten carbide, a hard and durable material that provides exceptional wear resistance and longevity. Tungsten carbide is a compound of tungsten and carbon, known for its hardness, thermal resistance, and ability to maintain a sharp edge even after extensive use.

Design:

Carbide drills for PCBs are specifically designed with precision and accuracy in mind. They feature a sharp point and spiral flutes that allow for efficient chip removal during the drilling process. The drills are typically available in a range of diameters, from as small as 0.1 mm to larger sizes, depending on the specific requirements of the PCB design.

Types:

- Standard Drills: Used for general-purpose drilling in PCB manufacturing.

- Micro Drills: Designed for extremely fine holes, often required in high-density PCBs.

- Reverse Shank Drills: Used for general purpose drilling with a common shank size and larger head.

1. Printed Circuit Board Manufacturing:

- Hole Drilling: The primary application of carbide PCB drills is in drilling holes for vias, through-hole components, and mounting points. Vias connect different layers of a PCB, while through-holes are used to insert component leads.

- Microvias: These drills are also used for creating microvias in high-density interconnect (HDI) PCBs, which are essential for modern electronic devices that require compact and high-performance circuitry.

2. Prototype Development:

- In prototype development, carbide drills are used to create precise holes for testing and assembling PCB designs before mass production.

3. High-Speed Drilling:

- Due to the hardness and heat resistance of carbide, these drills are ideal for high-speed drilling operations, which are common in automated PCB manufacturing processes.

4. Fine Pitch Drilling:

- Carbide drills are suitable for fine-pitch drilling, where extremely small and closely spaced holes are required. This is particularly important in PCBs for smartphones, laptops, and other compact electronic devices.

5. Multi-Layer PCB Manufacturing:

- These drills are essential in the production of multi-layer PCBs, where precision and accuracy are crucial for maintaining the integrity of connections between different layers.

6. Aerospace and Medical Electronics:

- In specialized industries such as aerospace and medical electronics, carbide drills are used for creating highly reliable PCBs that must withstand harsh environments and meet stringent quality standards.

7. Repair and Rework:

- Carbide drills are also employed in the repair and rework of existing PCBs, allowing for the replacement of components or the modification of the board layout without damaging the surrounding material.

Advantages of Using Carbide PCB Drills

- Durability: Carbide drills last longer than standard steel drills, reducing the need for frequent replacements.

- Precision: The sharpness and design of carbide drills ensure clean, accurate holes with minimal burrs or damage to the PCB.

- Efficiency: Suitable for high-speed operations, carbide drills contribute to faster production cycles and improved manufacturing efficiency.

- Heat Resistance: Carbide’s ability to withstand high temperatures allows for continuous drilling without loss of performance or risk of overheating.

- Variety: Printed Circuit board drills come in number, fraction, letter, and mm sizes

- Cost: PCB drills are a low cost option, and can be resharpened for high use applications

- Collet locating rings: Precise location of the collet ring allows for quick tool change without having to reset machine drill depth.

PCB Drill Applications

- PCB Drill: Can drill both through and depth holes in PCB materials such as FR4, polyimide, Teflon, and many others

- Other Industrial uses: PCB drills can be used to drill aluminum, copper, and even steel, preferably used with cutting fluids. They can also be used to drill carbon fiber.

- Hobby Tools: PCB drills are great options for wood working and plastic.

The “rules of the tools” apply. What this means is that all unused tools can be returned for a full refund (minus freight), no questions asked.

Share